Framing Systems

Framing Systems

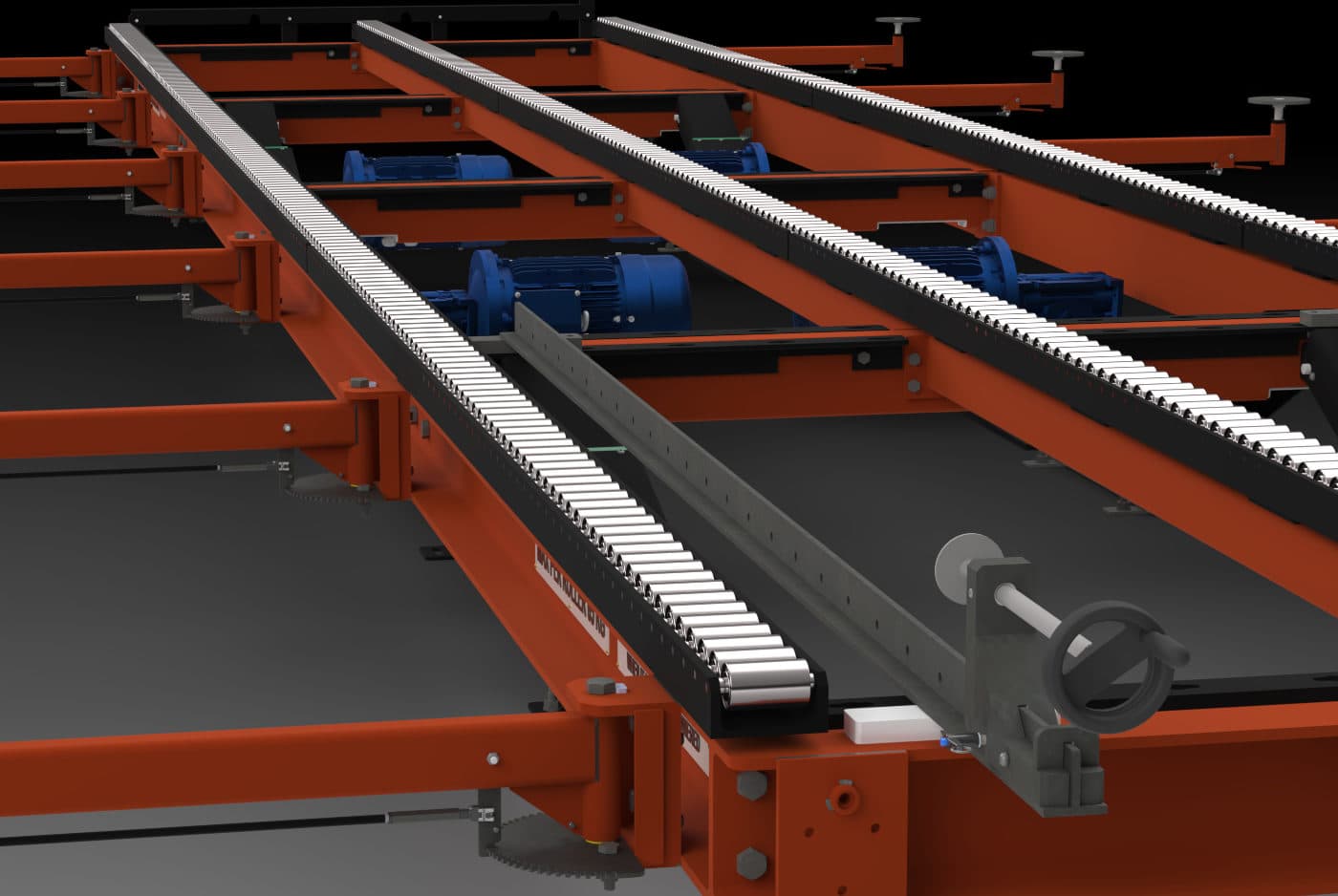

As specialists in factory automation, we build adaptable framing systems that deliver a high return on investment through significant gains in efficiency and productivity. Engineered to streamline the fabrication of wall, floor and roof panels with speed, precision and repeatability, our framing solutions can scale effortlessly to meet dynamic production schedules and changing market conditions for modular manufacturing.

Whether you manufacture with light-gauge steel or engineered timber in skilled or semi-skilled factory environments, we tailor framing solutions to suit your factory setup. Our systems are modular by design and can be easily configured to support variable throughput, factory expansions and new technologies.

We engineer standalone production machinery and complete framing production lines, with system configurations that can include:

- Cutting and routing systems

- High-speed roll-forming tracks

- Automated framing stations

- Panel assembly and squaring boards

- Storing and clamping tables

- Butterfly tables

- Guided rail systems for panel transfer and transport

- Panel handling, turning and transferring units

- Vacuum lifters

- Multi-function bridges

- Finishing and integration

- Insulation stations

- Sheathing lines

- Fastening systems

- Quality control systems

- Integrated control software (CAD)

Our framing systems evolve with your business, keeping your production at the forefront of modular manufacturing.

Framing Systems Datasheets

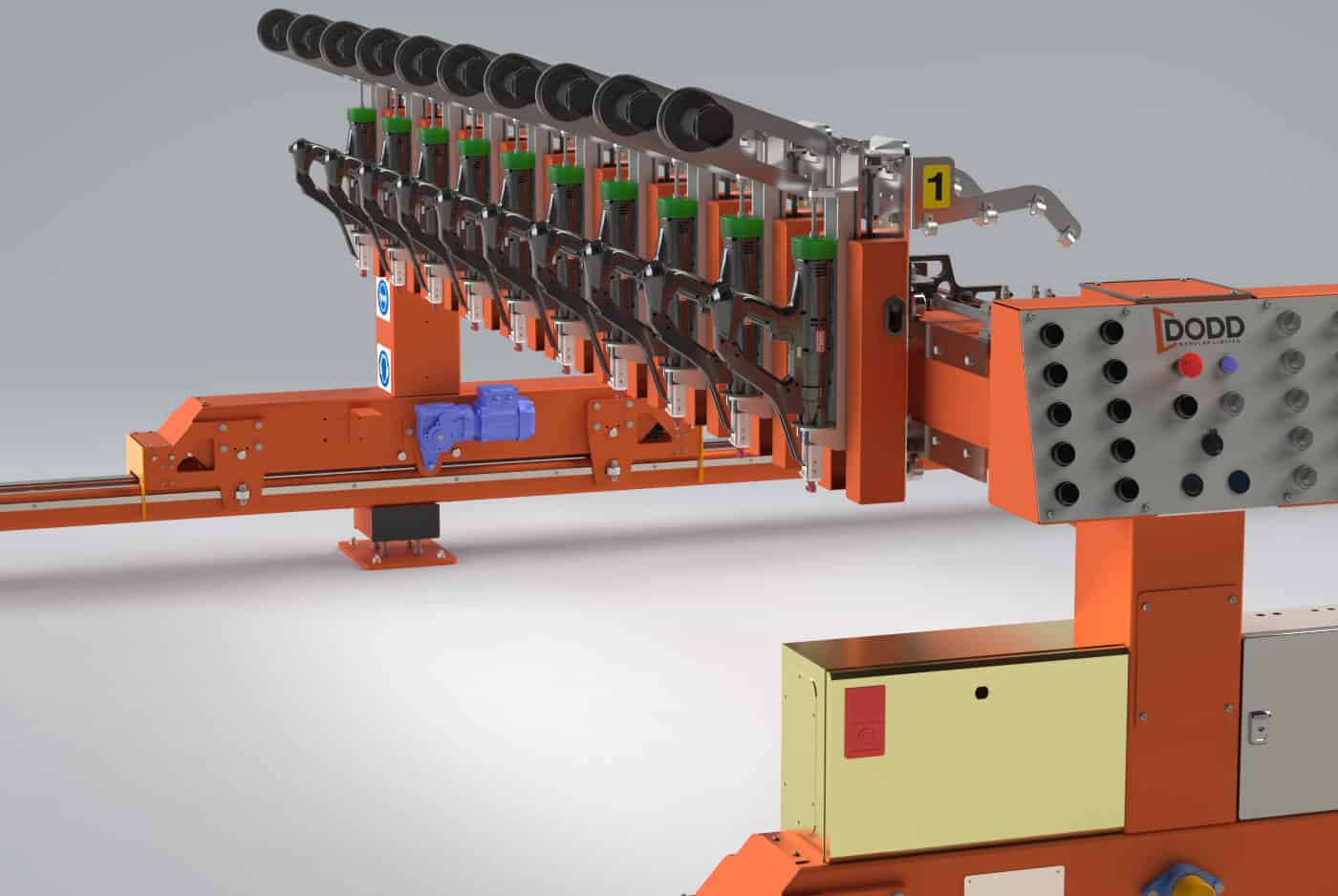

SFS-100 – Steel Framing Screwbridge

Featuring synchronized screwguns above & below, the system installs top & bottom fixings in a single pass.

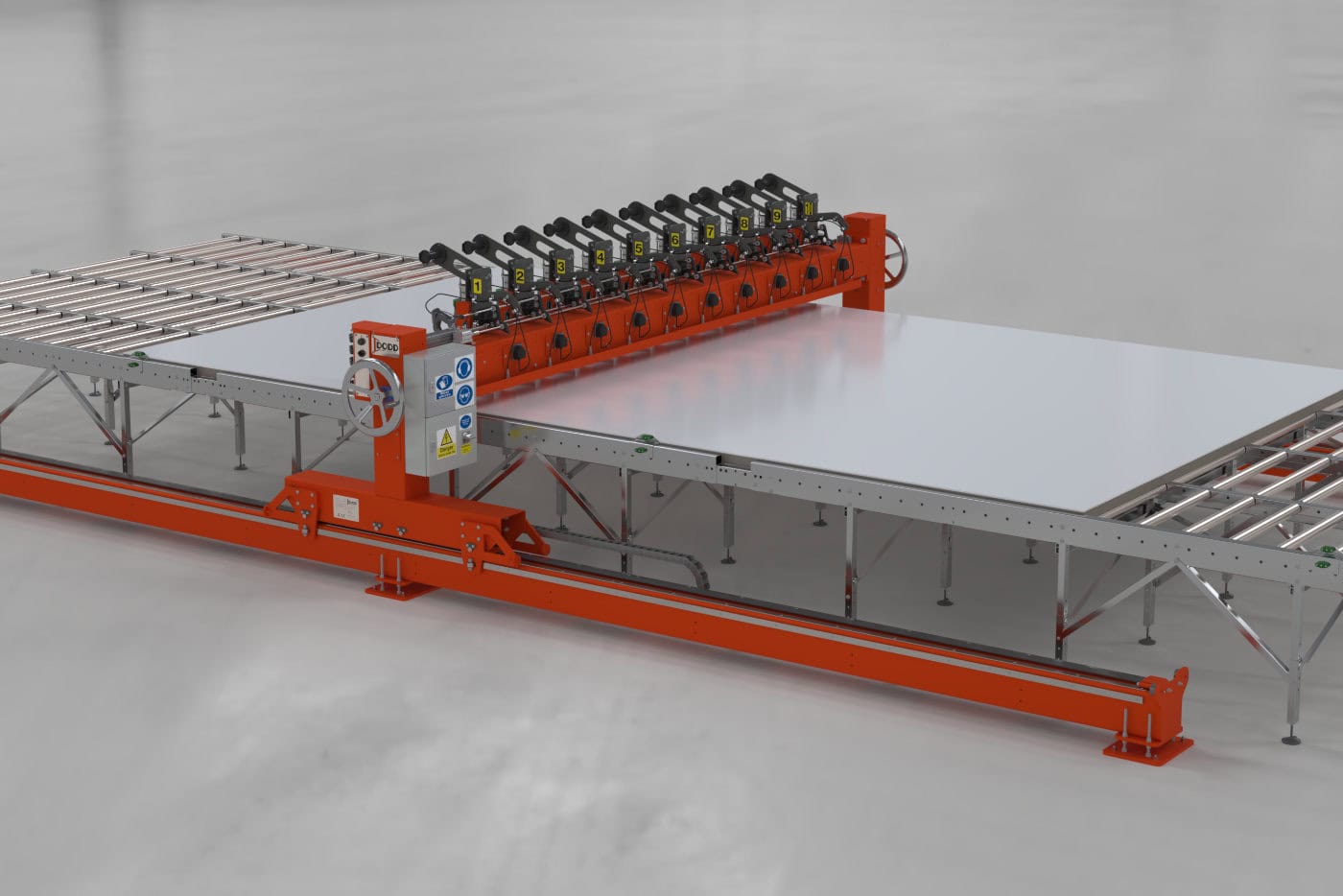

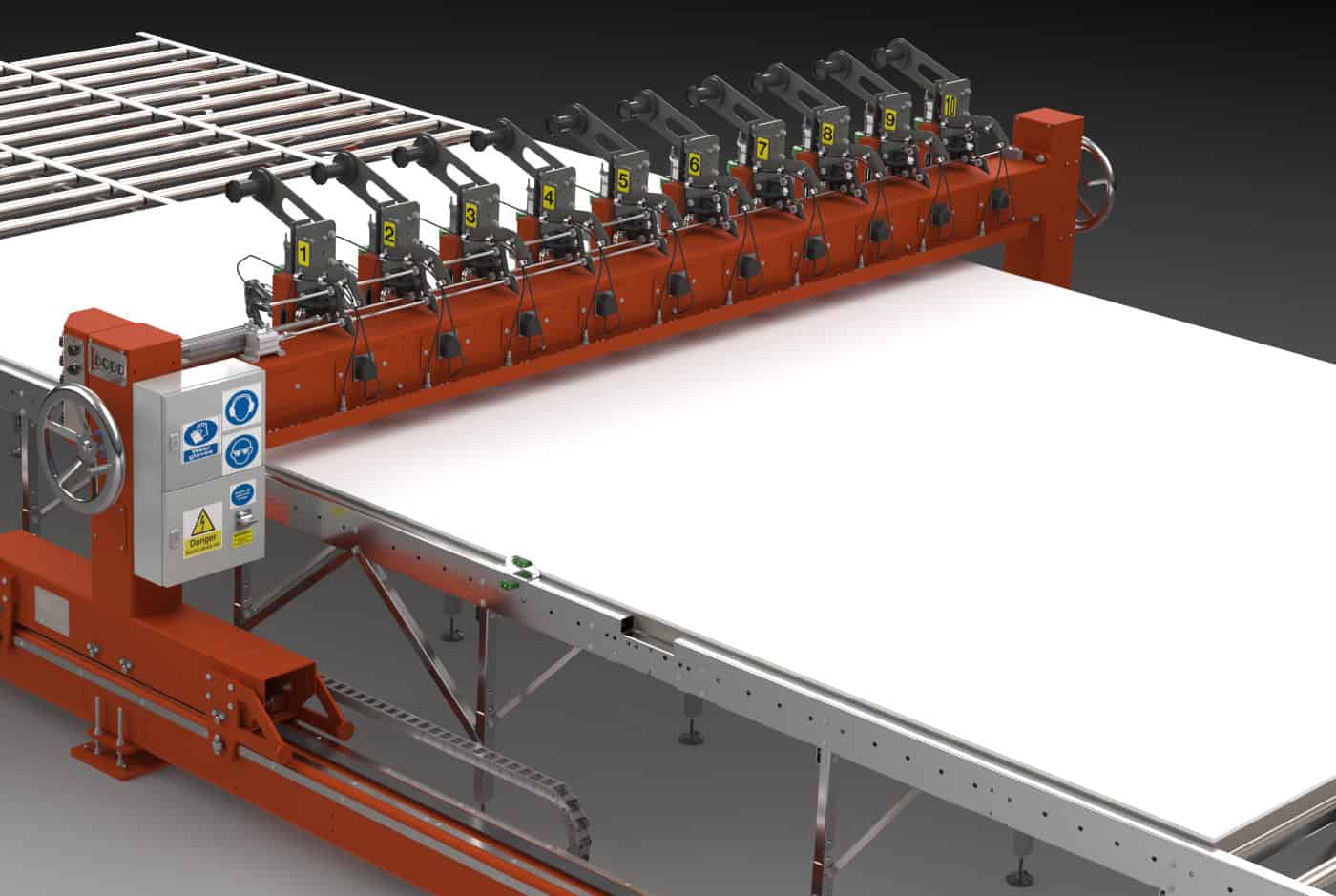

SCB-200 – Screwbridge

Equipped with multiple collated screw guns & operator-controlled positioning, to deliver consistent screw placement with minimal manual effort.

SCB-400 – Powered Screwbridge

Equipped with multiple collated screw fed guns & auto-controlled positioning, delivers consistent screw placement with no manual input.

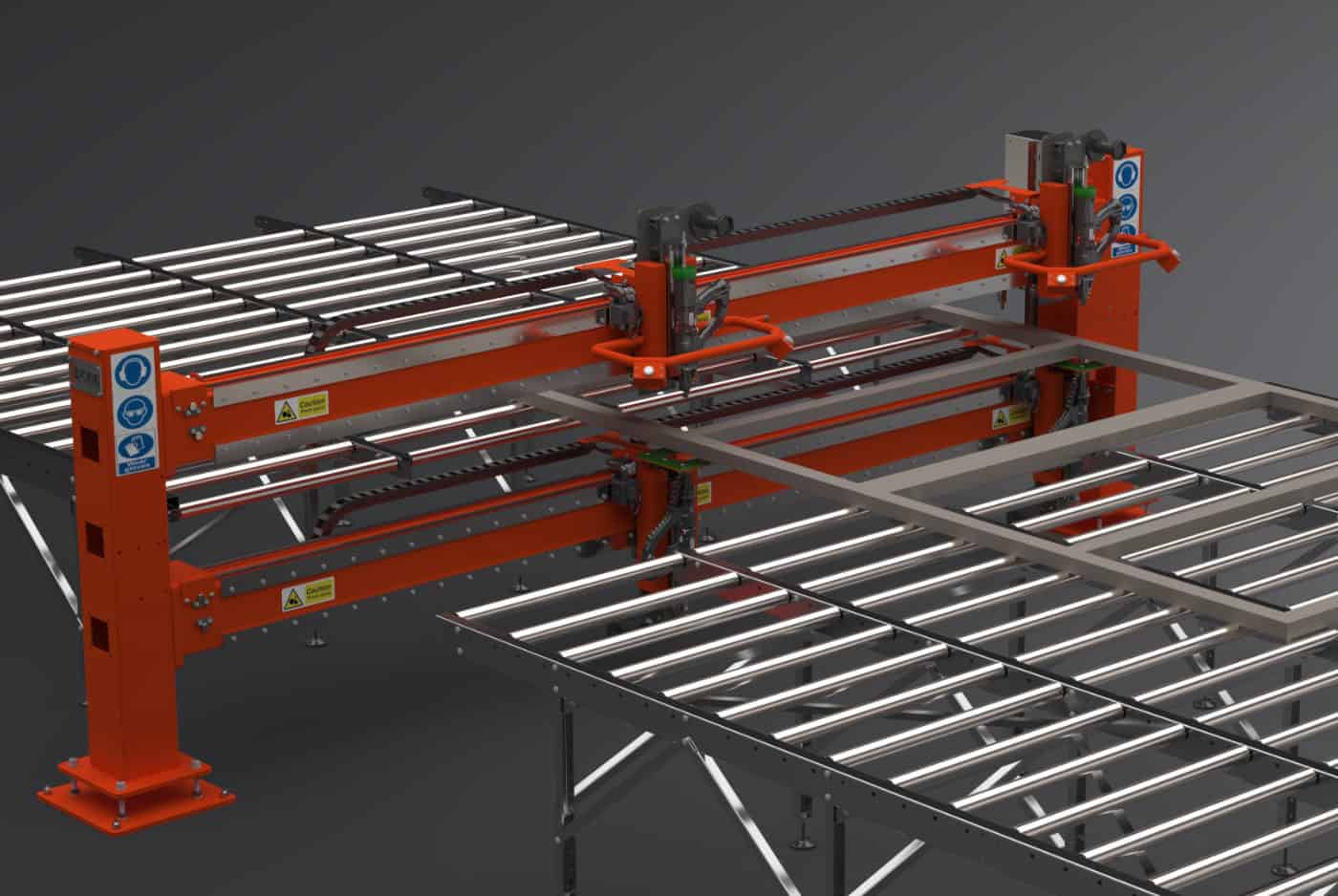

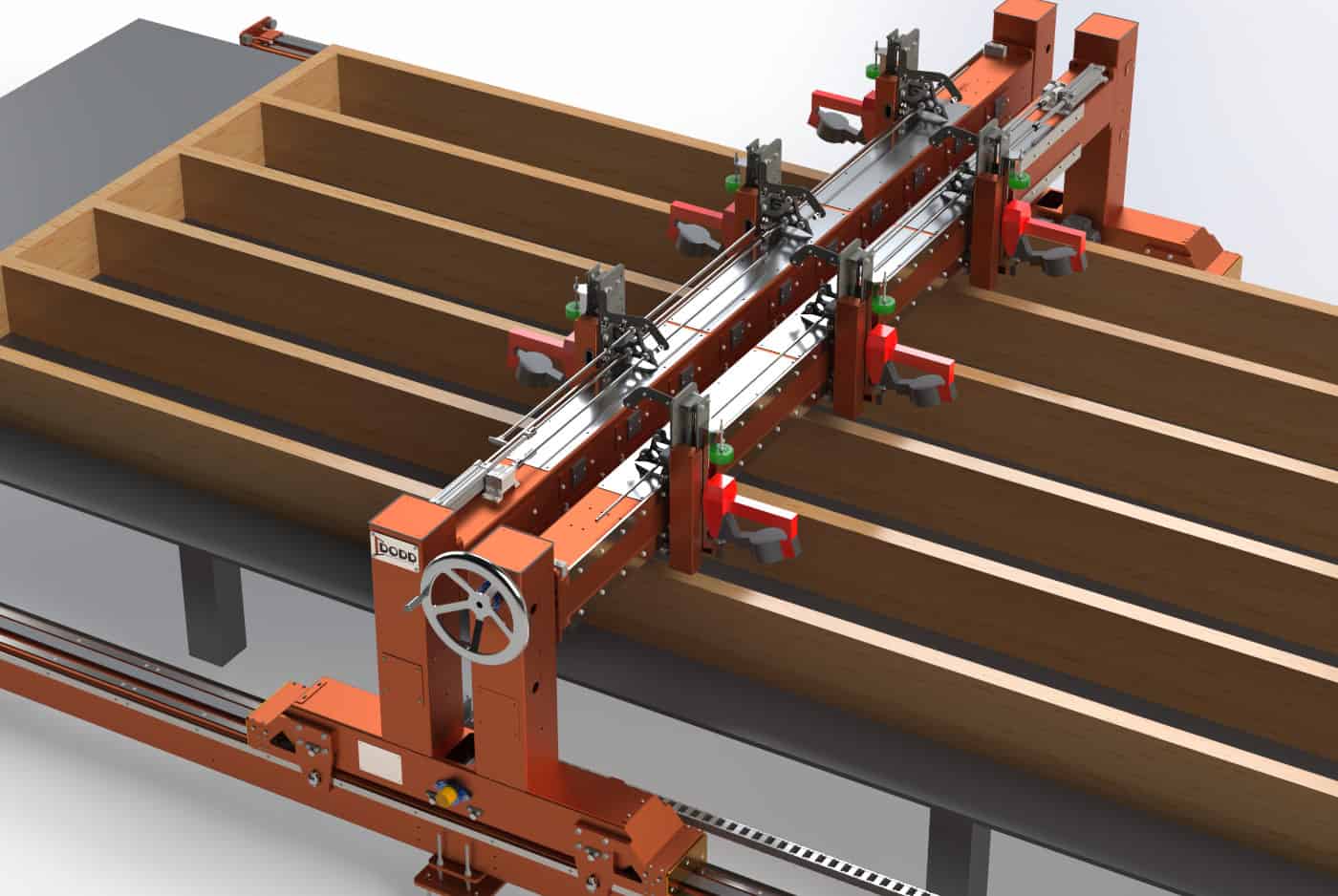

FTS-100 – Framing Table System

Streamline the fabrication of wall, floor and roof panels with speed, precision and repeatability.

LTS-100 – Lift Table System

Work safer & smarter with ergonomic height controls. Efficient panel finishing by combining ergonomic access, precision alignment, & easy integration into your modular build process.

NGB-100 – Nailbridge

Equipped with multiple magazine fed nail

guns and semi-automated controlled positioning, delivering consistent nail placement with minimal no manual input.